Chemistry has over the decades been able to develop very complex transformations in order to produce multifunctional molecules. Despite these important advances, we are still using round bottom flasks and batch reactors to perform such transformations as 200 years ago.

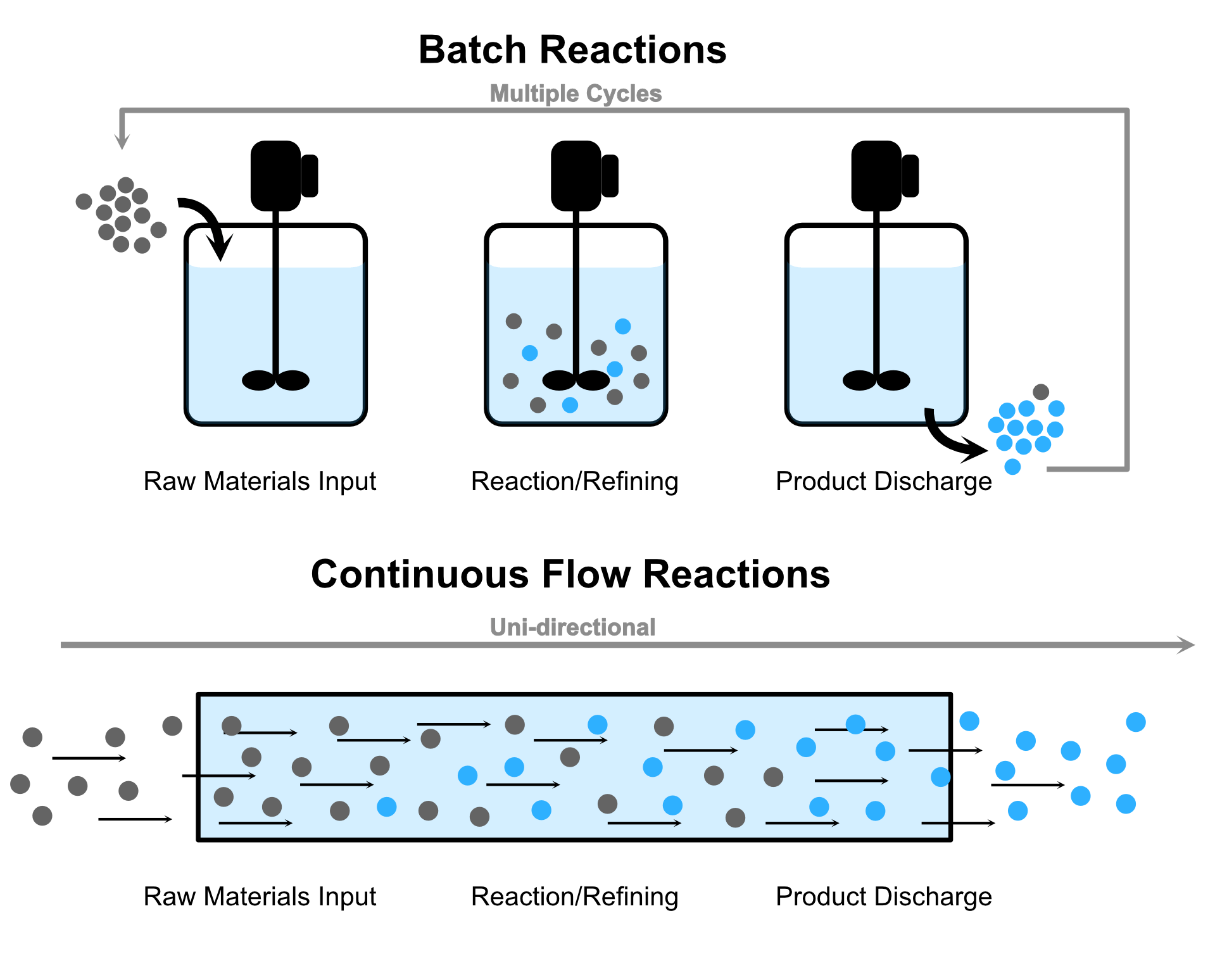

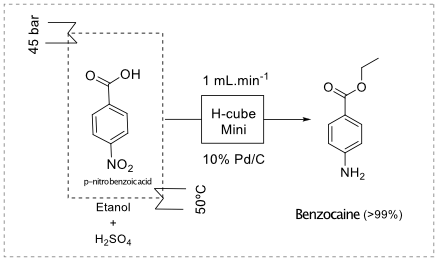

Continuous flow synthesis, also known as flow chemistry technology is an innovative technology in which chemical reactions are performed in continuously flowing streams within narrow channels. Until recently, the flow technology was the right choice only for very large systems, with low degree of complexity or chemical sophistication, such as petrochemicals.

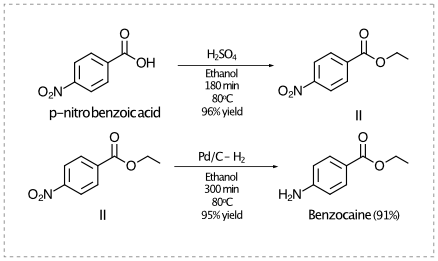

Correlated with disruptive manufacturing technologies, such as metal 3D printing, flow chemistry is changing the way we do synthesis today in lab and in industrial scale. Complex and regulated industries such as the pharmaceutical industry are taking advantages of this technology to become more integrated, to develop more efficient processes and to reduce timelines from drug discovery to the market.